A large number of industries in many industries use processes in which heat is transferred between different fluids. The basic principle of heat transfer is extremely simple, which is that two liquids at different temperatures are placed in contact with a heat-conducting baffle (wall of a corrugated tube). Heat is transferred from a hotter liquid to a colder liquid until they reach the same temperature level. In industry, this is done in heat exchangers (heat exchanger, dimrot and coil) of various types and styles, usually specially built for the process and heat transfer conditions.

A large number of industries in many industries use processes in which heat is transferred between different fluids. The basic principle of heat transfer is extremely simple, which is that two liquids at different temperatures are placed in contact with a heat-conducting baffle (wall of a corrugated tube). Heat is transferred from a hotter liquid to a colder liquid until they reach the same temperature level. In industry, this is done in heat exchangers (heat exchanger, dimrot and coil) of various types and styles, usually specially built for the process and heat transfer conditions.

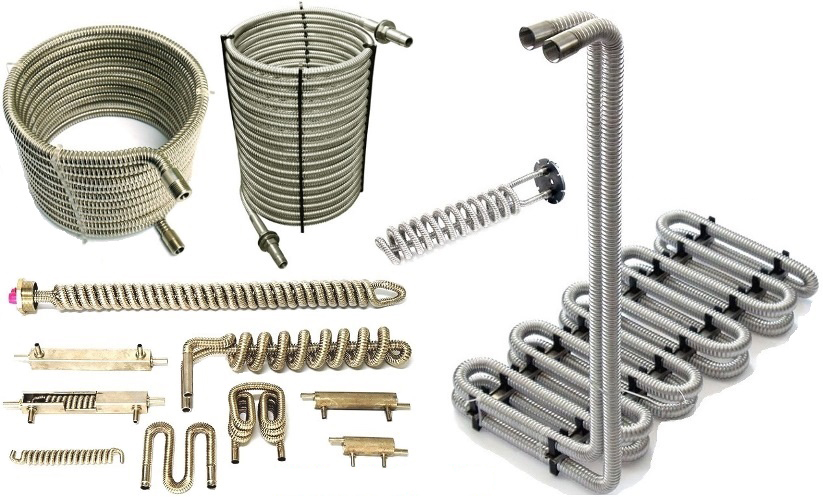

Corrugated stainless steel bellows heat exchangers

The second factor controlling heat transfer is the area of the heat-conducting baffle provided in heat exchangers by the heat flow. The larger the area, the more will be the amount of heat that will be supplied at a given time, taking into account the temperature difference inside the heat exchanger.

The third factor, perhaps the most important, has a controllable heat transfer - this is the thickness of the heat exchanger baffle, at which heat flows inward or outward from each of the liquids are transferred faster. The smaller the thickness of the heat exchanger baffle, the faster the heat transfer. The rate of warm flow to the heat exchangers will also matter.

The third factor, perhaps the most important, has a controllable heat transfer - this is the thickness of the heat exchanger baffle, at which heat flows inward or outward from each of the liquids are transferred faster. The smaller the thickness of the heat exchanger baffle, the faster the heat transfer. The rate of warm flow to the heat exchangers will also matter.

The resistance level for heat flow in a heat exchanger is a result of various factors, including the inherent thermal characteristics of the fluid, but can be very positively influenced by the design by generating turbulence in the fluid. To prevent the creation of a thermally stable static "boundary layer" of fluid in contact with the heat transfer surface.

The corrugated tube creates good turbulence inside to mix the heat flow from the inner walls to the central heat flow.

The fourth factor affecting the flow of heat across the conductive barrier between fluids is the quality of the heat exchanger material. The material selected must be compatible with the process fluids, it must not corrode or contaminate the food, it must have an appropriate level of mechanical strength to withstand operating temperatures and pressures, and it must have low resistance to heat flow so that this is not critical. factor in the heat transfer process.

Corrugated heat exchange pipes are made of stainless steel AISI 304, AISI 304L, AISI 316, AISI 316L.

Heat transfer values, usually specified by the customer, can directly affect the design in terms of the selection of corrugated pipe size and thickness and materials for production.

The values of the partial heat transfer coefficients largely depend on the nature of the liquid, but also, most importantly, on the geometry of the heat exchange surfaces where they are in contact.

Spiral stainless steel bellows tube

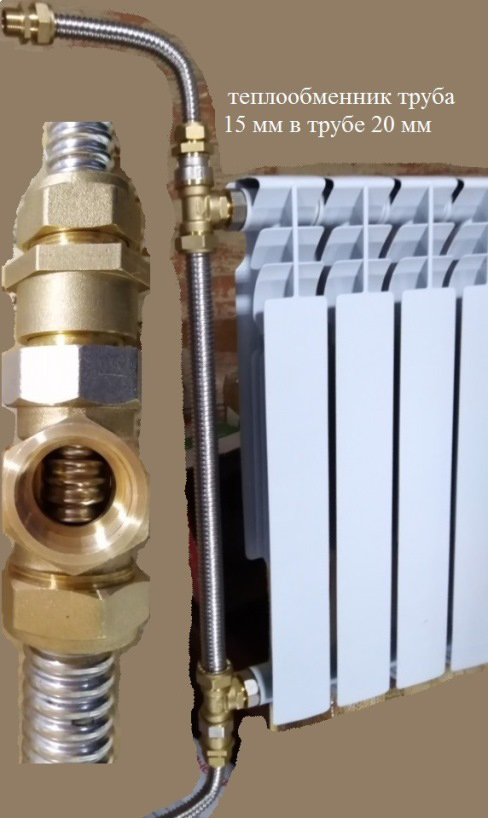

Bellows heat exchangers are used in hot water supply and heating systems, in petrochemical, chemical and oil and gas production, in refrigeration systems and air conditioning systems, where, as mentioned above, they are used to heat or cool water, chemicals and other liquids.

- In particular, bellows heat exchangers are easy to repair, thanks to a unique developed technology that makes it possible to replace bellows tubes in a bundle individually and in just 15 minutes, extremely quickly.

- Bellows heat exchangers have a more than threefold increase in heat transfer; when they are created, thin-walled corrugated heat exchangers are used.

- The special corrugated profile gives the heat exchange tube spring properties, which makes it insensitive to water hammer and thermal expansion.

- The advantage of corrugated pipes, compared to other materials, is in particular that lime deposits are not possible: due to vibrations, expansions and turbulence, even with very calcareous water, no deposits are formed on the walls of corrugated pipes.

The functioning of a bellows heat exchanger is based on enhancing the heat exchange process by destroying the boundary layer flow on both sides of the heat exchange surface due to the use of corrugated pipes.

The functioning of a bellows heat exchanger is based on enhancing the heat exchange process by destroying the boundary layer flow on both sides of the heat exchange surface due to the use of corrugated pipes.

With turbulence in the movement of coolants, a counterflow is realized, which contributes to an increase in temperature mixing and an increase in the specific thermal power of the heat exchanger.

Screw type corrugated pipes are ideal products for heat exchangers

Other advantages of corrugated stainless steel heat exchangers:

- no corrosion, stainless steel grade Aisi 304, AISI 316

- increased surface area in relation to straight pipes

- faster heat transfer due to the thin pipe wall from 0.3 mm to 0.4 mm depending on the nominal width and pressure)

- smallest bending radius high flexibility of the heat exchanger (pipes can be bent manually, no bending machine required)

- constant bending diameter of points and radius

- compact installation of a corrugated tube heat exchanger

The corrugation of the pipe increases the turbulence of the heat flow - the miscibility of the various flows increases. The applications of corrugated tube in heat exchangers are much more efficient than conventional straight tube heat exchangers.

Corrugated stainless steel tube in corrugated shape for heat exchanger ensures maximum efficiency. The screw-type corrugated pipe is corrosion resistant and offers extremely low pressure drop. Good heat dissipation can be obtained with corrugated tubes in tube-in-tube heat exchangers.